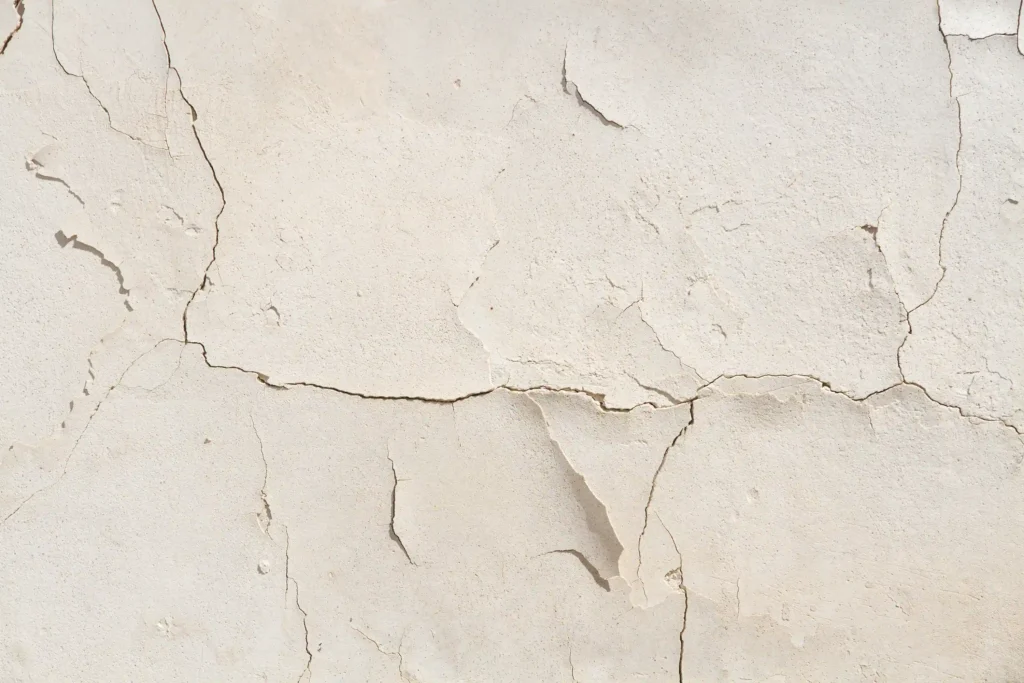

Cracking and shedding of interior and exterior wall putty powder are pervasive challenges in construction, leading to costly repairs, rework, and compromised aesthetics. Understanding the causes of putty cracking and shedding is crucial for durable finishes.

As leading manufacturers of Hydroxypropyl Methyl Cellulose (HPMC) and Redispersible Polymer Powder (RDP), key additives for superior building materials, mikazone delves into the science behind these failures and provides effective treatment methods for putty problems.

Common Causes of Putty Cracking and Shedding

1. Inadequate Substrate Preparation:

- Cause: Dust, oil, grease, loose particles, or excessive substrate absorbency prevent proper putty powder adhesion. Uneven surfaces create stress points.

- Result: Weak bonding leads directly to putty powder delamination and stress-related cracks in putty.

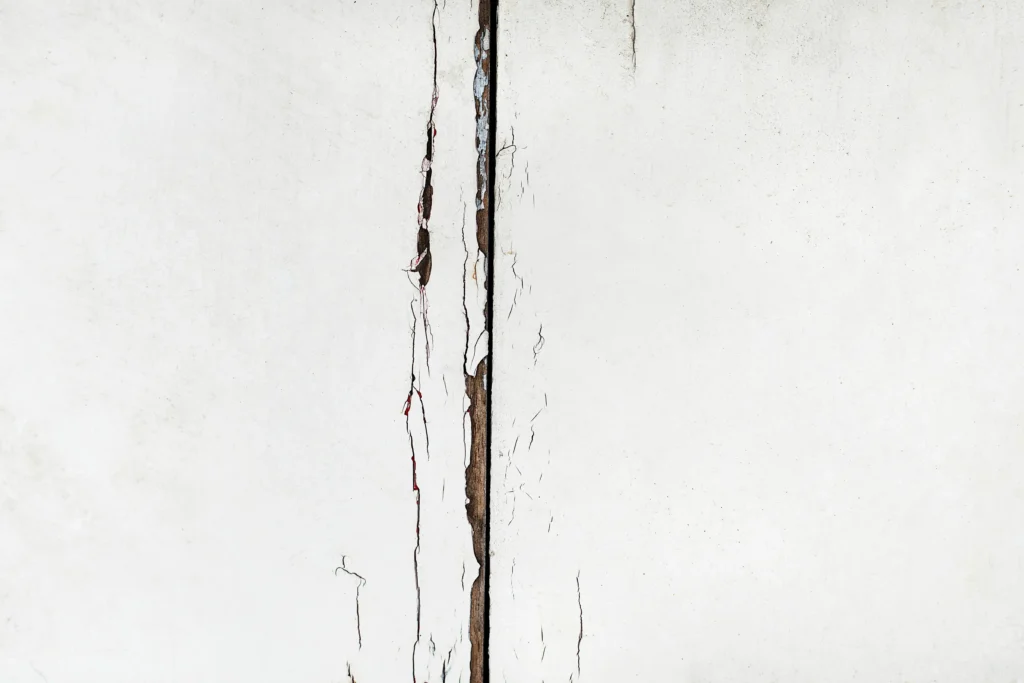

2. Weak or Unsound Substrate Beneath:

- Cause: Applying wall putty over crumbling, powdery, or low-strength bases (like poor mortar or uncured plaster). The substrate lacks the strength for putty application.

- Result: Movement or failure of the weak layer causes putty powder cracking and subsequent shedding of putty.

3. Incorrect Putty Application Thickness & Technique:

- Cause: Applying putty too thickly (>2-3mm per coat) causes excessive shrinkage upon drying. Uneven application creates weak zones prone to plaster cracking.

- Result: Severe shrinkage cracks in putty and localized areas of putty powder shedding.

4. Poor Curing Conditions:

Cause: Rapid drying (high temp, low humidity, wind) prevents proper hydration and strength development. Low temperatures drastically slow curing, weakening the putty film.

Result: Premature cracking of wall putty, brittleness, and increased risk of future powdering and shedding.

5. Excessive Substrate Movement or Vibration:

Cause: Structural settling, thermal expansion/contraction, or vibration exceeding the flexibility of standard putty.

Result: Characteristic stress cracks in plaster, often propagating from joints, leading to potential putty adhesion failure.

6. Low-Quality Putty Formulation (Lacking Key Polymers):

Cause: Insufficient or inferior binders (cement/gypsum), poor filler gradation, low water retention, and, critically, insufficient polymer modification. This is where the absence of adequate Hydroxypropyl Methyl Cellulose (HPMC) and Redispersible Polymer Powder (RDP) becomes the core issue.

Result: High shrinkage, poor putty powder cohesion, weak adhesion to substrate, low flexibility, and brittleness.

How to Fix Putty Cracking and Shedding

1. Meticulous Substrate Preparation:

- Rigorously clean (remove all dust, contaminants), repair cracks/holes, and level the substrate. Apply a high-quality primer for putty adhesion on absorbent or weak surfaces. Ensure substrate integrity is sound before any putty powder application.

2. Master Proper Application Techniques:

- Apply wall putty in thin, uniform coats (1-2mm max per coat for finishes). Allow full drying/curing between coats as per manufacturer’s guidelines. Proper troweling technique is vital to avoid putty application problems.

3. Control the Curing Environment:

- Protect fresh putty application from direct sun, wind, and extreme temperatures (5°C – 35°C / 41°F – 95°F ideal). Maintain moderate humidity. Use protective sheeting. Never force-dry. Proper curing prevents putty cracks.

4. Repair Existing Cracks and Shedding Areas Correctly:

- For hairline cracks in putty: Light sand, clean, apply a thin topcoat of high-quality, flexible putty (formulated with RDP).

- For significant shedding of putty or large cracks: Remove ALL loose material to sound substrate. Clean deeply. Apply a bonding primer. Fill with a polymer-modified patching compound. Refinish with premium putty. Address any underlying structural issues first.

5. Use High-Performance, Polymer-Modified Putty:

- Specify or formulate putties incorporating optimal levels of premium additives:

Hydroxypropyl Methyl Cellulose (HPMC):

HPMC combats putty powder cracking and shedding primarily by retaining water for complete hydration and forming a reinforcing polymer film that enhances adhesion, cohesion, internal strength, and surface integrity.

Its contributions to workability, air entrainment, and open time further ensure a dense, uniform, well-bonded, and properly cured putty layer that is inherently more resistant to these common failure modes.

Typically, the dosage of Hydroxypropyl Methyl Cellulose ranges from 0.2 to 0.5% of total weight.

Redispersible Polymer Powder:

Redispersible Polymer Powder (RDP) plays a fundamental role in preventing cracking and shedding in putty powder by transforming the brittle cementitious matrix into a flexible, cohesive, and highly adherent composite material.

Typical dosage ranges from 1% to 4% by weight of the dry mix, depending on the required performance level.

Conclusion: Stop Cracks & Shedding at the Source

Preventing putty powder cracking and putty powder shedding requires a holistic approach: impeccable substrate prep, skilled application, controlled curing, and crucially, using high-performance putty powder engineered with essential polymers. Hydroxypropyl Methyl Cellulose (HPMC) and Redispersible Polymer Powder (RDP) are not mere additives; they are the scientific solution for achieving durable, flexible, and reliably adherent finishes that withstand real-world stresses.

As expert manufacturers of premium HPMC and RDP specifically designed for construction applications like putty, Mikazone provides the essential raw materials that empower formulators to create putties that solve these persistent failure modes. Experience the difference that consistent, high-purity HPMC for putty powder and RDP for enhanced putty performance can make.

Ready to formulate putties that resist cracking and shedding? Contact us today to discuss how our HPMC and Redispersible Polymer Powder can elevate your product’s performance and reliability!