Flexible tile adhesives excel in bonding strength, crack resistance, and adaptability to substrate movement, ideal for high-moisture areas, heated floors, and environments with thermal fluctuations.

Mikazone’s advanced R&D has engineered a superior formula combining ordinary cement, quartz sand, hydroxypropyl methylcellulose(HPMC), flexible redispersible polymer powder, polypropylene fibers, and water-reducing agents. These ingredients synergize to enhance flexibility, water resistance, and long-term durability, ensuring reliable performance in dynamic construction settings.

Flexible Tile Adhesive Formulation

Cement 42.5R : 35%

Quartz Sand (40-70 mesh ): 55%

HPMC (Mikazone®MK100P) : 0.2-0.5%

Redispersible Polymer Powder (Mikavae®MK3510N) : 3-8%

Polycarboxylate Superplasticizer (Mikaultra®PC201): 0.1-0.5%

Polypropylene fiber: 0.1-0.5%

Flexible Tile Adhesives: S1 vs. S2 Classifications

Flexible tile adhesives are specialized bonding agents designed to accommodate substrate movement, thermal expansion, and structural stresses, ensuring crack-resistant installations. According to EN 12004 standards, they are categorized into two performance classes:

S1 (Deformability ≥ 2.5–5 mm): Ideal for moderate movement scenarios, such as residential floors, interior walls, and commercial spaces with controlled environmental shifts. Offers balanced flexibility and adhesion.

S2 (Deformability > 5 mm): Engineered for extreme deformation resistance, suitable for high-stress areas like heated floors, exterior façades, or structures exposed to significant temperature/humidity fluctuations. Enhanced polymer content ensures superior elasticity and long-term durability under dynamic conditions.

Both classes prioritize crack resistance, but S2 excels in high-risk environments demanding maximum adaptability.

6 Key Components in Flexible Tile Adhesive Formulation

1. Cement 42.5R

Cement 42.5R, a high-early-strength Portland cement, is a key binder in flexible tile adhesive formulations. Its rapid hardening properties ensure quick initial adhesion, which is critical for vertical applications or fast-paced projects.

With a compressive strength of ≥42.5 MPa after 28 days, it provides a robust structural base while maintaining compatibility with redispersible latex powder. Paired with HPMC and polypropylene fibers, it forms a cohesive matrix that balances rigidity and flexibility, meeting both S1 and S2 performance standards for deformability and crack resistance.

2. Quartz Sand

Quartz sand, a key inert filler, enhances dimensional stability, mechanical strength, and shrinkage resistance in flexible tile adhesives.

Combined with polymers and cement, quartz sand balances flexibility and load-bearing capacity, while its low water absorption (≤1%) minimizes efflorescence risks. Sustainable and cost-effective, it ensures long-term performance in thermal cycling and high-stress environments.

3. Hydroxypropyl Methyl Cellulose (HPMC)

Hydroxypropyl Methylcellulose (HPMC) is a multifunctional cellulose ether widely used in flexible tile adhesives to optimize workability, adhesion, and long-term performance.

3.1 Benefits of HPMC in Flexible Tile Adhesive

Water Retention

- Critical Function: HPMC forms a colloid in water, slowing evaporation and ensuring complete cement hydration, even on porous substrates or in dry conditions.

- Impact on Strength: Prevents premature drying, avoiding weak bonds and cracks.

Workability Enhancement

- Anti-Sag Properties: Adjusts mortar viscosity to prevent vertical application slippage (e.g., wall tiles).

- Smooth Application: Improves spreadability and tooling, reducing air entrapment.

Extended Open Time

- Adjustable Setting: By retaining moisture, HPMC extends the time for tile repositioning, crucial for large-format or complex installations.

- Balance with Speed: Combines with rapid-setting cement (e.g., 42.5R) to maintain efficiency.

Durability & Compatibility

- Alkali Resistance: Stable in high-pH cement environments, avoiding degradation.

- Temperature Tolerance: Maintains performance in both hot and cold climates.

3.2 Typical Dosage & Selection

Usage Rate: 0.1–0.4% of total dry mix (excess may delay curing or reduce strength).

Key Parameters:

Substitution Degree: MS (methyl) and DS (hydroxypropyl) ratios affect solubility and thermal gelation.

Particle Size: Fine powders dissolve faster, ensuring uniform dispersion.

Viscosity Gradation: HPMC grades (e.g., 40,000–100,000 mPa·s) are selected based on adhesive class:

S1 Formulations: Mid-viscosity (60,000–80,000) balances sag resistance and spreadability.

S2 Formulations: Higher viscosity (100,000+) maximizes crack-bridging capacity.

4. Flexible Redispersible Polymer Powder

Redispersible Polymer Powder (RDP) is categorized as rigid, neutral, or flexible based on glass transition temperature (Tg). Flexible RDP, with low Tg ( -20°C to 0°C), offers elasticity, crack resistance, and stress absorption.

Ideal for flexible tile adhesives, it enhances adhesion on deformable substrates (e.g., gypsum, heated floors), prevents debonding under thermal/mechanical stress, and complies with EN 12004 standards.

4.1 Benefits of Redispersible Polymer Powder in Flexible Tile Adhesive

Enhanced Flexibility

- Low-Tg Latex Powders ( -20°C to 0°C): Provide high elasticity, allowing the adhesive to absorb substrate movements (thermal expansion, vibration) without cracking.

- Polymer Film Formation: Forms a continuous, flexible network within the cement matrix, improving tensile strength by 50–100% compared to unmodified mortars.

Superior Adhesion Strength

- Bonding Mechanism: Chemically adheres to tile backs (ceramic, porcelain) and substrates (concrete, gypsum).

- Wet Adhesion: Maintains grip even in humid or wet environments (e.g., bathrooms, pools).

Improved Workability & Durability

- Water Resistance: Seals capillary pores, reducing water absorption and frost damage, and enhancing long-term durability in exterior applications.

- Anti-Slip & Sag Resistance: Adjusts mortar rheology for vertical application without sagging.

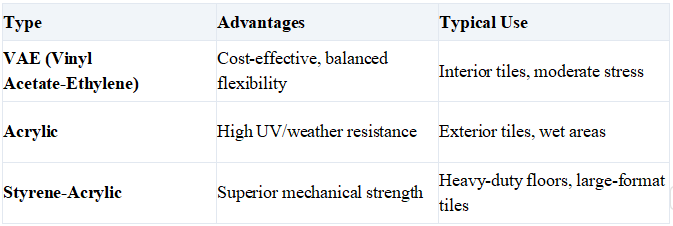

4.2 Key Types & Selection Guidelines

4.3 Dosage & Performance

Typical Range: 3–8% of total dry mix (exceeding 10% may delay curing or reduce compressive strength).

Impact of Dosage:

- Flexibility: A highly flexible tile adhesive formula requires a higher dosage of Redispersible Polymer Powder (e.g., 8% for S2-grade adhesives).

- Adhesion: Optimal at 5–6% for most substrates.

5. Polycarboxylate Superplasticizer (PCE)

Polycarboxylate superplasticizers (PCEs) are high-performance water-reducing admixtures that revolutionize flexible tile adhesive formulations by enhancing workability, strength, and durability while maintaining critical flexibility.

5.1 Benefits of Polycarboxylate Superplasticizers in Flexible Tile Adhesive

High Water Reduction:

- Reduces water demand by 20–40%, lowering the water-cement ratio to achieve higher density and 30–50% increased compressive strength (compared to traditional superplasticizers).

- Enables thin-bed applications (<3 mm) for large-format tiles by improving flowability without segregation.

Flexibility Retention:

- Maintains S1/S2 deformation capacity (EN 12004) by optimizing cement dispersion without over-rigidifying the matrix.

- Compatible with polymer modifiers (e.g., VAE latex powder) to balance strength and crack-bridging ability.

Controlled Workability:

- Adjusts mortar viscosity for anti-sag performance on vertical surfaces and smooth tooling.

- Extends open time (up to 30–40 minutes) when paired with HPMC, ensuring tile repositionability.

5.2 Recommended dosage

6. Polypropylene Fiber

Polypropylene (PP) fibers are synthetic reinforcement additives widely used in flexible tile adhesives to enhance crack resistance, dimensional stability, and long-term durability. These microfibers act as a three-dimensional reinforcement network, mitigating stress concentrations and improving the adhesive’s ability to withstand dynamic loads and substrate movements.

6.1 Benefits of Polypropylene Fiber in Flexible Tile Adhesive

Crack Control:

- Reduces plastic shrinkage cracks during curing by distributing internal stresses, improving surface integrity.

- Enhances post-cracking ductility, maintaining cohesion even after initial micro-crack formation.

Mechanical Reinforcement:

- Boosts flexural strength by 15–25% and impact resistance by up to 30% compared to unreinforced adhesives.

- Reduces delamination risk under thermal cycling (e.g., underfloor heating systems).

Durability:

- Limits water penetration by bridging capillary pores, enhancing freeze-thaw resistance (EN 1348).

- Resists alkali degradation (pH 12–13) in cementitious matrices, ensuring long-term stability.

6.2 Dosage & Selection Guidelines

Low Dosage (0.1–0.2%): Primarily for crack control in interior applications.

Medium Dosage (0.3–0.4%): Balances crack resistance and workability for exterior or heated floors.

High Dosage (0.5%): Reserved for heavy-duty industrial floors or seismic-prone regions.

Critical Note: Excess fibers (>0.6%) may hinder workability and tooling smoothness.

Summary

Flexible tile adhesive formulations vary slightly depending on application scenarios (e.g., interior/exterior, large-format tiles, or underfloor heating), but HPMC and redispersible polymer powder (RDP) remain indispensable additives for ensuring workability, adhesion, and flexibility.

Mikazone supplies high-quality HPMC, RDP, polycarboxylate superplasticizers (PCEs), and polypropylene (PP) fibers to elevate your adhesive’s performance-enhancing bond strength, crack resistance, and durability.

Beyond premium raw materials, Mikazone offers customized technical support, tailoring formulations to meet specific project requirements, whether optimizing open time, adjusting rheology, or improving sag resistance. For existing formulations underperforming in critical areas (e.g., shrinkage, water retention, or curing speed), our experts provide formulation modification services to transform subpar mixes into high-performance solutions.

Contact Mikazone today to unlock the full potential of your tile adhesive system, leveraging cutting-edge additives and science-driven expertise for superior results in demanding environments. Upgrade your formula now—reach out for a consultation!