C2 tile adhesive is the backbone of durable, crack-resistant tiling systems, ensuring long-term performance in demanding environments. A precise blend of cement, aggregates, and functional additives, its formulation directly impacts bond strength, flexibility, and water resistance.

At Mikazone, we’ve engineered C2 formulations enhanced with essential additives like HPMC (hydroxypropyl methylcellulose) for optimal workability and Redispersible Polymer Powder (RPP) to boost adhesion and durability. Discover how our tailored solutions minimize installation failures and reduce maintenance costs.

Dive deeper to unlock the secrets of a formula trusted by professionals worldwide.

What is a C2 Tile Adhesive?

C2 tile adhesive is a high-performance cement-based adhesive designed for demanding tiling applications.

It offers enhanced bond strength (≥1.0 N/mm² per EN 12004) and improved water resistance, flexibility, and durability compared to standard C1 adhesives.

Suitable for wet areas (bathrooms, kitchens), exterior facades, and heavy tiles, it often includes polymer modifiers for deformability and long-term stability.

While C1 adhesives are cost-effective for basic tiling, C2 adhesives provide superior performance for demanding environments. The choice depends on tile type, substrate conditions, and exposure to moisture.

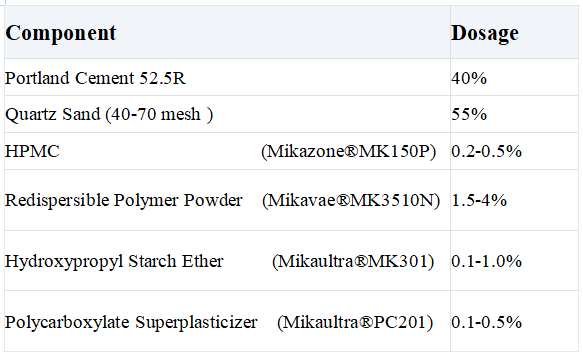

C2 Tile Adhesive Formulation

Portland Cement 52.5R: 40%

Quartz Sand (40-70 mesh ): 55%

HPMC (Mikazone®MK150P): 0.2-0.5%

Redispersible Polymer Powder (Mikavae®MK3510N): 1.5-4%

Hydroxypropyl Starch ether(Mikaultra®MK301): 0.1-1.0%

Polycarboxylate Superplasticizer (Mikaultra®PC201): 0.1-0.5%

6 Main Components of C2 Tile Adhesive Formula

1. Portland Cement 52.5R

2. Quartz Sand

3. Hydroxypropyl Methyl Cellulose (HPMC)

3.1 Benefits of HPMC in C2 Tile Adhesive

- Water Retention: HPMC forms a protective colloid that slows water evaporation, ensuring proper cement hydration. This improves adhesive strength development, especially in porous substrates or high-temperature conditions.

- Extended Open Time: It provides excellent slip resistance and extended open time, allowing tiles to be adjusted without losing bond strength.

- Sag Resistance: HPMC increases viscosity, preventing tile slippage on vertical surfaces while maintaining smooth application.

- Adhesion Enhancement: Improves wet adhesion to tiles and substrates, critical for C2-classified adhesives (higher bond strength requirements than C1).

3.2 HPMC Selection for C2 Formulations

Viscosity Range:

- Medium viscosity (e.g., 40,000–60,000 mPa·s): Balances sag resistance and workability.

- High viscosity (e.g., 100,000+ mPa·s): Used for thicker adhesives or vertical applications.

Dosage: Typically 0.2–0.5% of total dry mix, adjusted based on substrate, climate, and performance needs.

3.3 Formulation Tips of HPMC in C2 Tile Adhesive

- Combine with redispersible polymer powders for flexibility and enhanced adhesion.

- Optimize HPMC grade based on powder fineness and mixing water demand.

- Test for compatibility with other additives (e.g., Hydroxypropyl Starch ether, superplasticizers).

4. Redispersible Polymer Powder(RDP)

Redispersible Polymer Powder (RDP) is a crucial additive in C2 tile adhesive formulations, significantly improving flexibility, adhesion, and durability to meet EN 12004 performance standards.

4.1 Benefits of Redispersible Polymer Powder in C2 Tile Adhesives

Enhanced Adhesion Strength

Improves bond strength to various substrates (concrete, cement boards, gypsum, etc.).

Crack Resistance

Prevents cracks due to substrate movement or thermal cycling.

Enhanced Durability

Enhances hydrophobicity, reducing water absorption and improving long-term performance.

Improved Workability

Enhances open time while maintaining adjustability.

4.2 Common Redispersible Polymer Powder Types

Vinyl Acetate-Ethylene (VAE): Balances adhesion, flexibility, and cost-effectiveness. Ideal for interior and moderate-moisture applications.

Acrylic-Based RDP: Offers superior UV stability, alkali resistance, and water repellency, suitable for exterior and high-humidity environments.

Styrene-Acrylic: Provides high mechanical strength and durability for heavy-duty applications.

Vinyl Acetate-Versatate (VeoVa): Enhances hydrophobicity and chemical resistance for demanding conditions.

4.3 Typical Dosage of Redispersible Polymer Powder

5.Silicone Hydrophobic Powder

Silicone hydrophobic powder is a key additive in C2 tile adhesives, enhancing water resistance, durability, and long-term performance. It modifies the adhesive’s surface properties, reducing water absorption while maintaining strong bonding capabilities.

5.1 Functions of Silicone Hydrophobic Powder in C2 Tile Adhesives

1. Moisture Resistance

- Forms a hydrophobic barrier within the adhesive matrix, preventing water penetration.

- Reduces efflorescence and degradation caused by freeze-thaw cycles.

2. Improved Durability

- Enhances resistance to alkali attack and chemical exposure (e.g., in wet areas like bathrooms and pools).

- Maintains bond strength in humid or submerged conditions.

3. Enhanced Workability

- Extends the open time and maintains the adjustability of the tile

- Compatible with other additives (e.g., HPMC, redispersible polymer powders).

4. Reduced Cracking

- Minimizes capillary water absorption, lowering the risk of shrinkage cracks.

- Enhances stress distribution, preventing micro-crack formation and improving long-term dimensional stability of the adhesive layer.

5.2 Typical Dosage in C2 Tile Adhesives

0.1%–1.0%(by weight of dry mix), depending on desired hydrophobicity.

6 Hydroxypropyl Starch Ether

Hydroxypropyl Starch Ether (HPS) is a modified starch derivative widely used as an additive in construction materials, particularly in C2 tile adhesives. It enhances the performance of the adhesive by improving workability, water retention, and open time, while also contributing to mechanical properties.

6.1 Benefits of Hydroxypropyl Starch Ether in C2 Tile Adhesives

Water Retention: HPS significantly improves water retention, preventing rapid water loss to porous substrates (e.g., concrete, plaster). This ensures proper cement hydration, critical for adhesive strength development.

Workability & Sag Resistance: It acts as a thickener, providing optimal viscosity and anti-sag properties for vertical tile applications (e.g., large-format tiles).

Extended Open Time: HPS slows down the drying process, allowing longer adjustment time for tiles without compromising adhesion.

Improved Adhesion & Cohesion: Enhances the bond strength between the adhesive and tiles/substrate, reducing the risk of tile slippage or delamination.

6.2 Typical Dosage of Hydroxypropyl Starch Ether in C2 Adhesives

0.1–0.5% of the total dry mix weight (varies based on formulation requirements).

Summary

Tile adhesive formulations vary slightly across different applications, but additives like HPMC and RDP remain indispensable for optimal performance.

Mikazone provides premium additives, including HPMC, RDP, starch ethers, and superplasticizers, engineered to elevate your product’s performance in any environment.

But we’re more than a supplier. Facing unique challenges? Our experts craft customized formulations for extreme climates, heavy traffic, or complex substrates, ensuring unmatched adhesion and longevity. Whether optimizing curing speed or freeze-thaw resistance, Mikazone tailors solutions to your exact needs.

Contact Mikazone today—transform your formulations with precision and reliability!