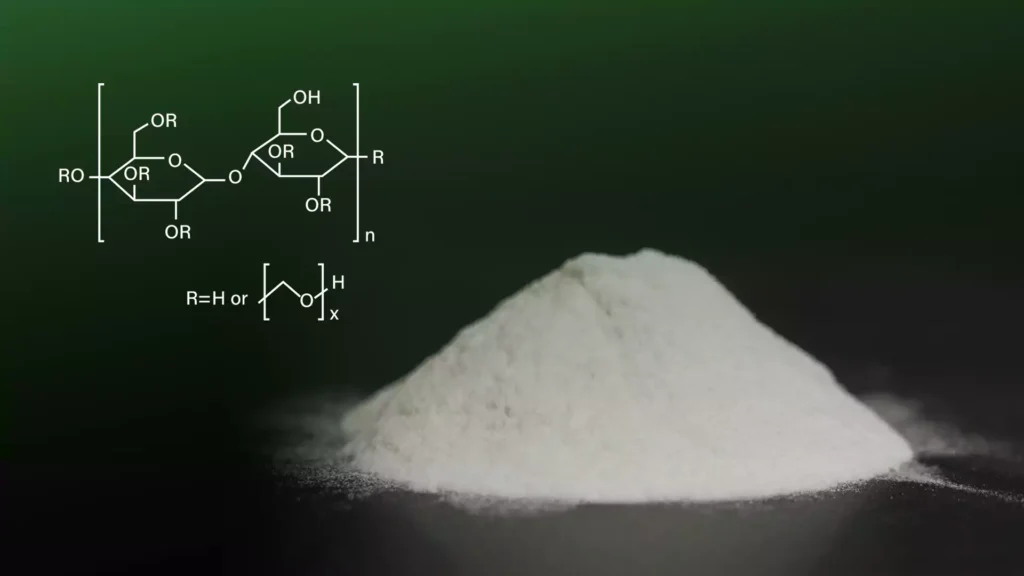

What is HEC?

Hydroxyethylcellulose (HEC) is an important hydroxyalkyl cellulose, a white or off-white, odorless, tasteless, and freely flowing powder.

HEC powder is soluble in both cold and hot water. It is used in various fields such as construction cement mortars, pharmaceuticals, food, and petroleum drilling. It functions in thickening, suspending, dispersing, emulsifying, bonding, as well as moisture retention and colloidal protection.

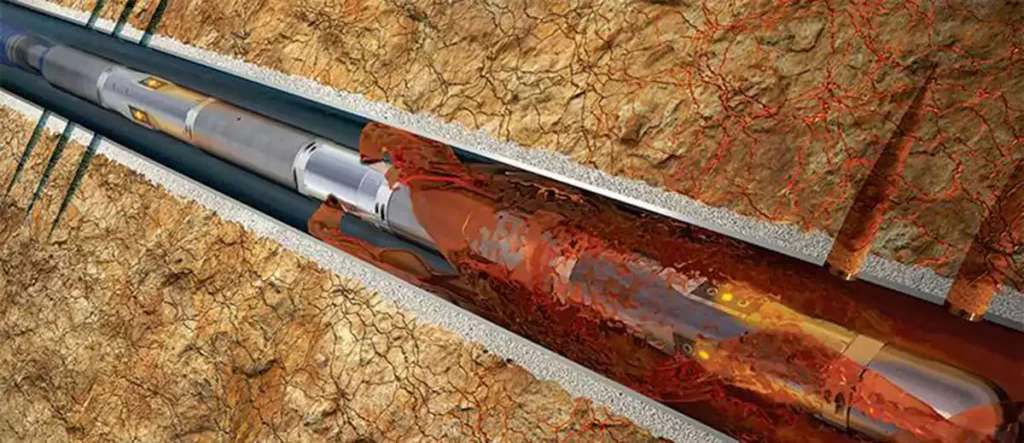

HEC in Oil Drilling

Due to its excellent properties, such as good water solubility, salt tolerance, and no gel point, HEC is used as a drilling fluid, fracturing fluid, well completion, and workover additive in the petroleum drilling industry.

It provides improved performance for petroleum drilling operations. In various muds used for drilling, cementing, and fracturing, HEC acts as a viscosifier, enabling the mud to achieve good fluidity and stability. It also enhances the mud’s carrying capacity, allowing a large amount of water to transfer from the mud into the oil layer, thereby stabilizing the oil layer’s production capacity.

1 - HEC in Drilling Fluids

Due to its properties such as thickening, suspending, and lubricating, HEC, when used in drilling mud, can cool down iron filings and cuttings, carry debris to the surface, and improve the mud’s rock-carrying capacity. In oilfields, it has proven highly effective as a hole-cleaning and sand-carrying fluid.

Downhole, under high shear conditions, HEC exhibits unique rheological behavior that allows the drilling fluid’s viscosity to locally approach that of water.

—— On one hand, it increases the drilling speed, reduces heat buildup on the drill bit, and extends its service life.

—— On the other hand, it helps clean the wellbore and provides high permeability. This effect is particularly pronounced when used in hard rock formations, resulting in significant material savings.

HEC can also be used as a non-fermenting protective colloid for oil well treatment in drilling muds, and it is suitable for high-pressure (20 MPa) and high-temperature measurement applications.

One of the advantages of using HEC is that the same mud can be used for both drilling and well completion processes, reducing the dependence on other dispersants, thinners, and pH regulators. This makes fluid treatment, storage, and transportation more convenient.

2 - HEC in Fracturing Fluid

Studies have shown that when comparing the effectiveness of CMC, MHEC, HEC, HPC, and MC as components of fracturing fluids, HEC performs the best. In fracturing fluids, HEC significantly enhances various functions of the fluid.

Increased Viscosity

In fracturing fluids, HEC increases viscosity without affecting the oil reservoir, preventing fracture blockage and enabling successful fracturing of oil wells. It also has typical characteristics of water-based fracturing fluids, such as strong sand suspension capacity and low frictional resistance.

Improved Flowability

A water-alcohol mixture of 0.1% to 2% potassium, sodium, lead, and other high-iodine salts thickened with HEC, when injected under high pressure into the oil well for fracturing, can restore flowability within 48 hours.

Water-based fracturing fluids made with HEC leave minimal residue after liquefaction, making them particularly suitable for formations with low permeability where residue cannot be flushed out.

High-Temperature Durability

Using HEC helps prevent viscosity loss and fracturing of the oil reservoir due to high downhole temperatures. It remains effective even in downhole temperatures exceeding 371°C.

Prevents Blockage

HEC is not prone to degradation or contamination downhole, and it produces minimal residue, reducing the risk of blockages in the oil pathway or downhole pollution. It is far superior to plant-based gums commonly used in fracturing (e.g., guar gum).

3 - HEC in Well Completion and Workover

Ensuring Reservoir Production Capacity

Low-solids completion fluids made with HEC can prevent soil particles from blocking the pore spaces in the oil reservoir as they approach the reservoir, reducing fluid loss.

They also prevent excessive water from entering the reservoir, thus preserving its production capacity. HEC reduces the frictional resistance of the mud, lowering pump pressure and reducing power consumption. Its excellent salt tolerance ensures that no precipitation forms during acid treatments of the oil well.

Improving Operational Convenience

In completion and workover operations, HEC can carry rock cuttings and gravel from the wellbore, improving the radial and longitudinal distribution of sand and gravel. The polymer breakage process is also convenient, greatly simplifying the removal of workover and completion fluids.

In some exceptional cases, such as when downhole conditions are unusual, corrective measures may be needed to prevent mud from not returning to the surface during drilling or workover, causing circulating fluid loss. In these situations, high-concentration HEC-based loss-control fluids can be used.

Enhancing Cementing Performance

In cementing operations, low-viscosity HEC is typically used for its dual functionality:

1. It reduces hydraulic friction, lowers pump pressure, and increases the pumping rate.

2. HEC has excellent water retention properties, effectively preventing water from migrating into the formation and compromising cementing integrity, while also protecting the mechanical properties of the cement. Low-viscosity HEC is commonly used in cementing processes.

Quality HEC —— Specifically designed for high-quality drilling projects

To create high-quality, high-efficiency petroleum drilling operations, customized, high-quality HEC products are required, with strict control over performance factors such as enzymatic resistance, viscosity, and water retention.

Mikazone’s research team has carefully developed HEC products with exceptional quality and high efficiency, offering reliable supply capabilities. They specialize in providing the most suitable HEC solutions for petroleum drilling needs worldwide.